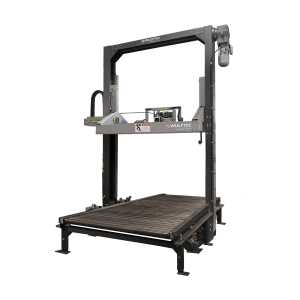

Description

Features:

- AC variable frequency drives as standard equipment on all machines. Why? Lower maintenance and better reliability—Wulftec equipment will save time and money

- NEMA 4/12 control panel dust tight and waterproof

- The control panel is neatly organized eliminating time otherwise lost searching for wires

- The control panel is UL508A approved

- Superior Electrical/Electronic Design including Allen Bradley CompactLogix PLC and AC drives

- User friendly touch screen offers a simple yet effective way to adjust and maintain your equipment

- All motors, proximity sensors, photoeyes and other sensors have quick disconnect cables that simplify installation and maintenance

- Photoeyes are maintenance free and protected

- All Wulftec structures are made of heavy-duty steel

- During the strapping cycle, the strapping head indexes towards the load before tensioning sequence, so tensioning and sealing are done against the side of the load.

- The strapping head is mounted on a movable assembly guided through linear bearings, and activated by an electric motor with a timing belt. The head has a load sensing device that detects the side of the load and tells the head movement to stop so tensioning and welding are done as close as possible to the product for maximum strap containment efficiency.

- The bottom section of the strapping arch can be a standard undertrack style or an electric motor driven pallet bayonet for “through-pallet” strapping or a combination of both.

- Up to 8 straps per minute may be applied, depending on strapping arch and package dimensions, strap quality and strap tension required.

- Electronic tension control through a variable frequency drive. Ensures consistent tension control regardless of the number of cycles and environmental conditions. The strap tension is adjustable from the touch screen.

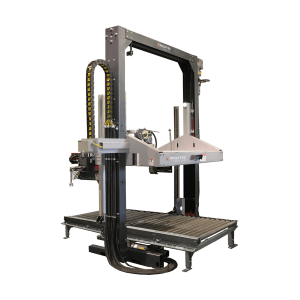

- The VarioMaster 9440 offers turntables, rotating cross and centering devices as an option for all handling needs…accommodating pallet and palletless loads.

- Our heavy-duty conveyors are second to none in the industry

- Coils of PET strapping with a core diameter of 16″ can be fitted to the high-speed dispensers, with a pulley block accumulation system and an electrical brake.

- Non-proprietary parts accessible on a local basis

- The best warranties in the industry

- 1-year on the strapping head and track

- 3-year unlimited cycle warranty

- 3-years on the steel structure

Specifications:

Structure:

- Heavy duty folded sheet metal uprights with upper frame structurally integrated with base for greater stability

Electrical Requirements:

- 460 V, 3 PH, 60 Hz, 15 A

Machine Dimensions:

- 205″ L x 35″ W x 85″ H

Load weight:

- Maximum load weight limited to conveyor capacity

Approximate Shipping weight:

- 1100 lbs

Production rate:

- 100 loads per hour

Options:

Contact us!