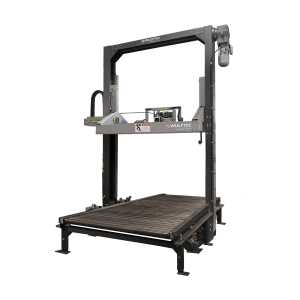

Description

Features:

- Allen Bradley CompactLogix L16ER PLC

- Allen Bradley PanelView Plus 7 6” color Touch Screen Interface

- 24V control system

- Current overload protection

- NEMA 4/12 control cabinet

- Autoheight sensing photoeye

- Power on/off lockable switch and indicator light

- 460VAC motor and contactor

- Two emergency stop stations (1 on panel / 1 on the platen)

- Manual function for strapping head and conveyors

- Variable compression setting from 150lbs to 2200lbs

- Intuitive alarms diagnostic on touch screen

- Machine and head cycle counter

- Reset function

- Strap track with under track configuration to allowing under pack strapping

- 2 fully adjustable strapping patterns

- 4 communications I/O signals with upstream & downstream system

- Allen Bradley PowerFlex 525 drive, 460VAC

- Allen Bradley series 100 contactor

- Alarm beacon

- 120 VAC outlet in control panel for service work

- High speed dispenser with pulley block accumulation system and electrical brake that can fits standard coils of PET strapping with a core diameter of 16″ and a width of 6″

- 3 HP AC gear motor with Allen Bradley Powerflex 525 AC drive

4′ long (along flow direction) platen with adjustable compression from 150lbs to 2200lbs. The floating platen supported by coil springs

Specifications:

Structure:

- Heavy duty folded sheet metal uprights with upper frame structurally integrated with base for greater stability

Electrical Requirements:

- 460 V, 3 PH, 60 Hz, 15 A

Machine Dimensions:

- 59″L x 139″W x 169″H

Load weight:

- Maximum load weight limited to conveyor capacity

Approximate Shipping weight:

- 5000 lbs

Production rate:

- 100 loads per hour

Options:

- Wrap height extension – 116in

- Pneumatic roping single

- 30″ NO-THREAD® Powered Pre-Stretch Carriage

- Custom color

- Electric top platen

- 60in round turntable

- Air Conditioner (104°F / 40°C and up)

- Transformer for Cold C temperature package

- Customized transformer

- 72in round turntable

- Safety Package

- Wrap height extension – 104in

- Wash-down motors for top platen

- Pneumatic roping dual

- 90° exit

- Wrap height extension – 92in

- Cold C (-31 to 5°F / -35 to -15°C) – Standard Plus and Deluxe panel

- Cold B (5 to 32°F / -15 to 0°C) – Standard panel

- Carriage adaptor bracket for 20″ film on 30″ carriage

- Dark load detection

- Fan & Exhaust

- Warning flashing light

- Electronic scale

- Electric dump valve

- Arm mounted cut & seal

- Cold A (32 to 41°F / 0 to 5°C)

- Upgrade from Standard to deluxe

- Foot pedal start / stop

- Lanyard remote

- Auto lube system

- Safety light curtains

- Remote push button station

- Pneumatic roping dual – extra photoeye

- Steel-it paint

- Safety control lockout

- Cold C (-31 to 5°F / -35 to -15°C)

- Epoxy paint

- Standard transformer

- Warning Alarm / Horn

- Safety fencing

- Cold B (5 to 32°F / -15 to 0°C) – Standard Plus and Deluxe panel

Wash down motors