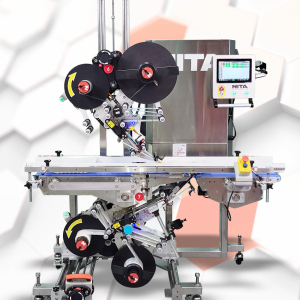

Description

Features :

- Applies a single side label and/or a second side label

- Dedicated to front, front/back, as well as a wraparound labeling applications

- Top lid label can be added

- Round, oval, square, rectangular shaped containers (bottles, jars, pails, etc.)

- 10 foot stainless steel conveyor bed, also optionally available in 8 and 12 foot configurations

- Activate each labeler individually or simultaneously – configurable in each recipe

- Conveyor frequency drive is 100% synchronized with label application

- 7″ Beijer HMI touch screen – with integrated controller

- Variable dispensing speed – up to 1570 inches/min

- Dispensing precision to ±1/32 inch

- Labels up to 6 inches wide (optional 9 inches)

- Optional top hold down belt

- Maintenance free Emerson servo motor and controller/amplifier

- Precision sealed bearings – eliminates all lubrication and risk of contaminants

- Unwind belt braking system allows for a smooth feed with no backlash and consistent web tension

- Electronically, touch screen controlled gap and product sensors – no manual positioning required

- One touch tensioning of media and threading with a simple ball detented nip roller system

- Extremely quick change-overs (tool free), all adjustment axes are equipped with graduated scales and color coded controls

- Sick retro-reflective photo-electric product sensing and optical label gap detection

- Optional Sick clear label sensor for opaque labels is ‘ teach ‘ configurable with no potentiometers with which to fiddle

Models:

- XP100

- XP200

- XP100T

- XP200T

- XP300T

- XP400T

Specifications:

Power/Motor/Controller:

- 200-240 VAC, Single Phase, 60 Hz, 10 amps

- (encoded) Synchronized SERVO

- Touch screen Human Machine Interface (HMI)

Labeler and label roll:

- Label rate: Synchronized 1570″/min (40 meters/min)

- Accuracy: =/- 1/16″

- Label: ½”(12.7 mm) wide x ½”(12.7 mm) long

- Label: 6″(152.4 mm) wide x 18″(457 mm) long

- Media roll size: 12″ (305 mm) OD on 3″ (76 mm) Core

Available Options:

- Wide web width up to 9″ (229mm)

- Clear label sensor

- Status lamp tower

- Low web sensor

- Zero down time

- Loose loop printer (for print & apply)

- Integration of any coder type

- Orientation system